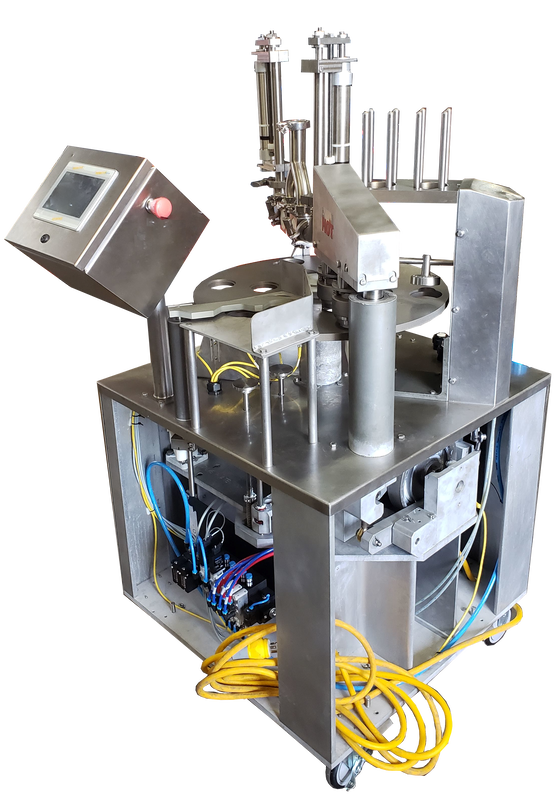

The Edgepack Two-Lane Rotary Filling Machine

|

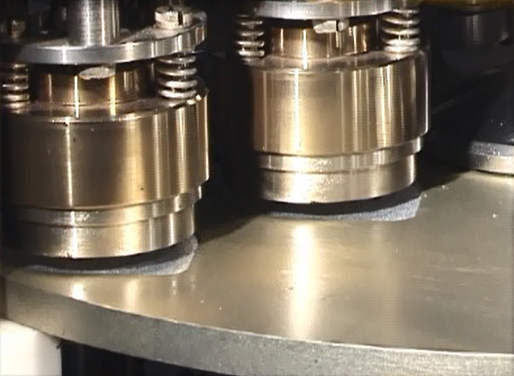

The standard tooling package features a carousel (the dial) that offers twin lanes for cups. The carousel is mechanically synchronous with the positions of each element

washdown touchscreen controlsAdjust speed temperature and other parameters using the Festo touch screen HMI.

|

Specifications

|

|

Edgerton Gear, Inc.

20 Gear Drive Edgerton, WI 53534 |

Phone: 608-884-9445

Fax: 608-884-3862 Email: [email protected] |

Copyright © 2003-2018

Edgerton Gear, Inc. All Rights Reserved |